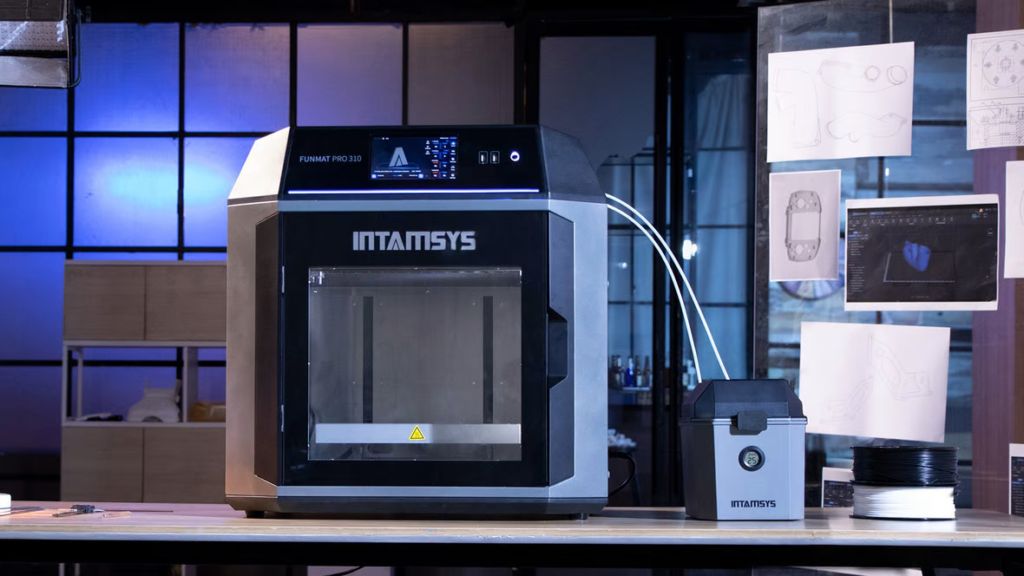

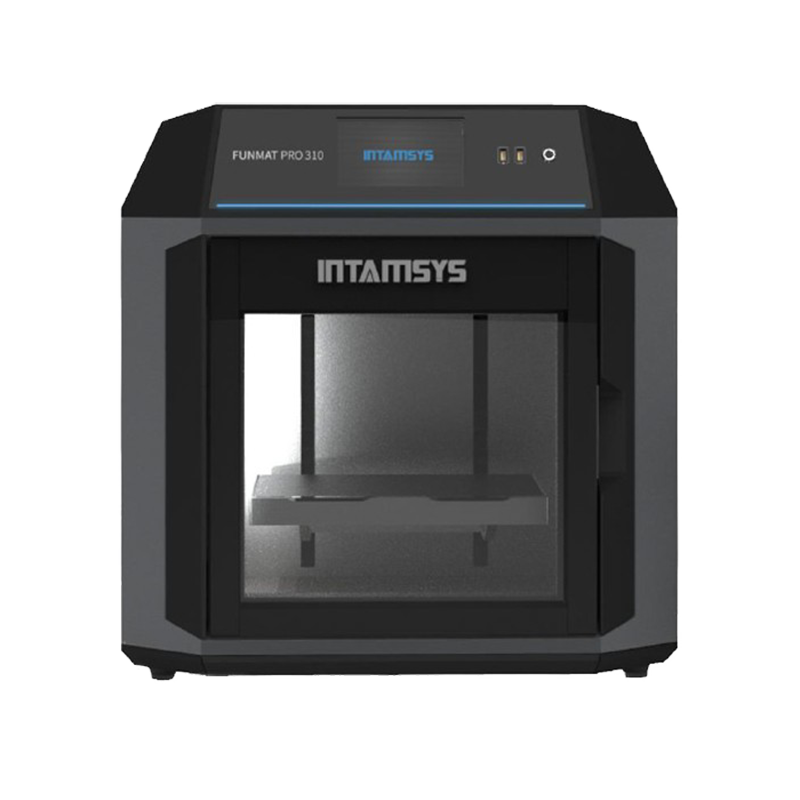

INTAMSYS FUNMAT Pro 310

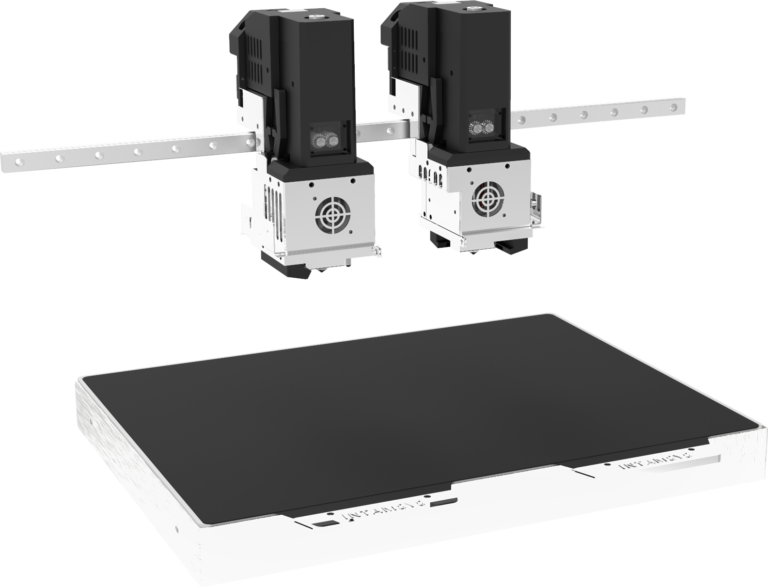

Printing capability and nozzle design with IDEX dual nozzle system

- Independent dual extruder (IDEX), for different printing modes as dual material printing, mirror printing, copy printing

- Modular design of the printhead, quick-change system for easy installation and replacement and convenient maintenance

- Dual-drive gear extruder, increase the contact surface for more torque and higher reliability

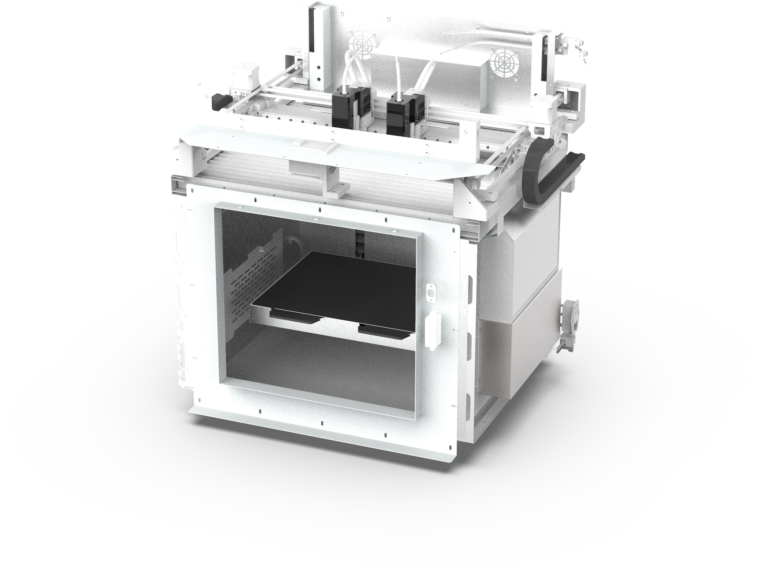

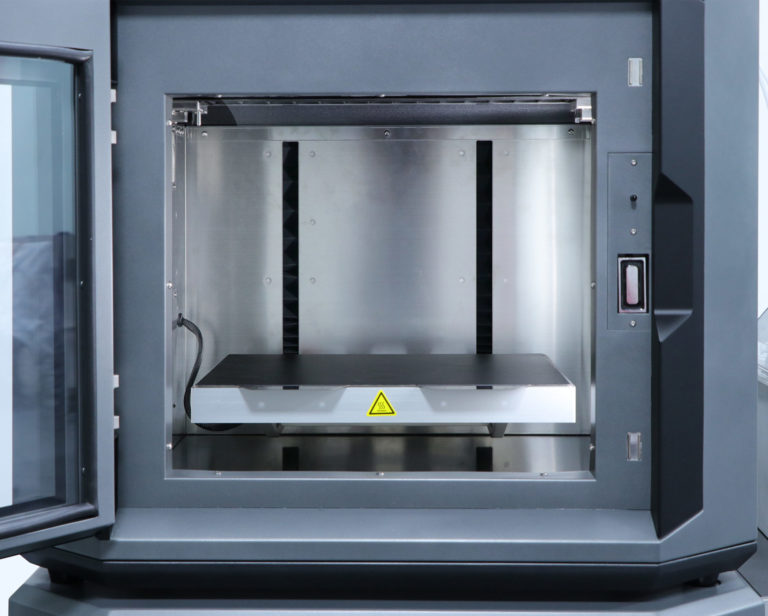

Thermal design for high strength and high accuracy

- The maximum temperature of the chamber is 100°C, the maximum heating temperature of the build plate is 160°C. It provides fast heating with its high-power output

- Excellent thermal design reduce thermal deformation of the mechanics and lower the shrinkage of models during printing, avoid warping and increase the interlayer-adhesion

- The maximum temperature of the nozzle is 300°C

- High-power nozzle heaters decrease the heating time and ensures that the nozzle is rapidly heated, and the filament is fully melted in the nozzle

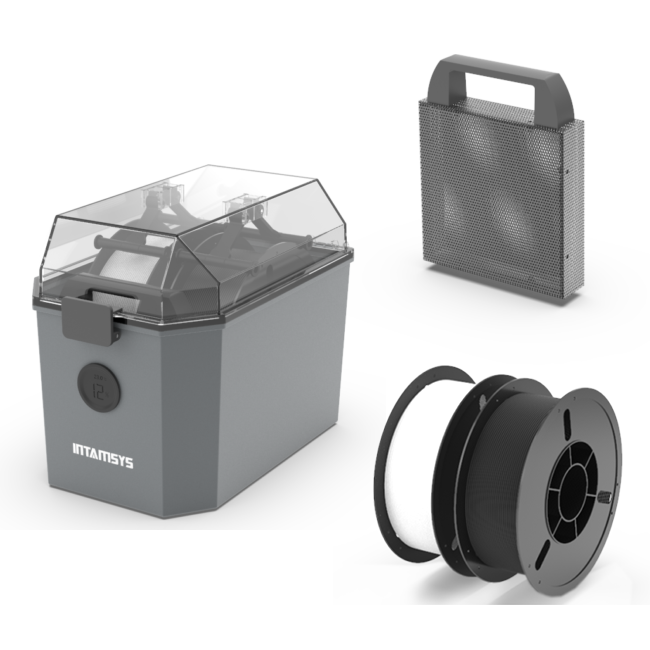

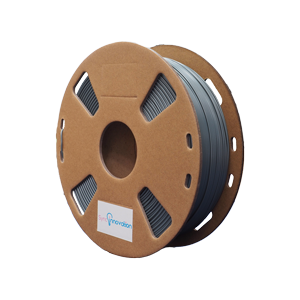

Independent Filament Box

- Overall sealed design with molecular sieve dehumidification, built-in temperature and humidity monitoring sensor.

- Independent design, easy to place and maintain

- Design of active fixing for spools, prevent the filaments from being loose and knotted

- Spool capacity: 2*1kg

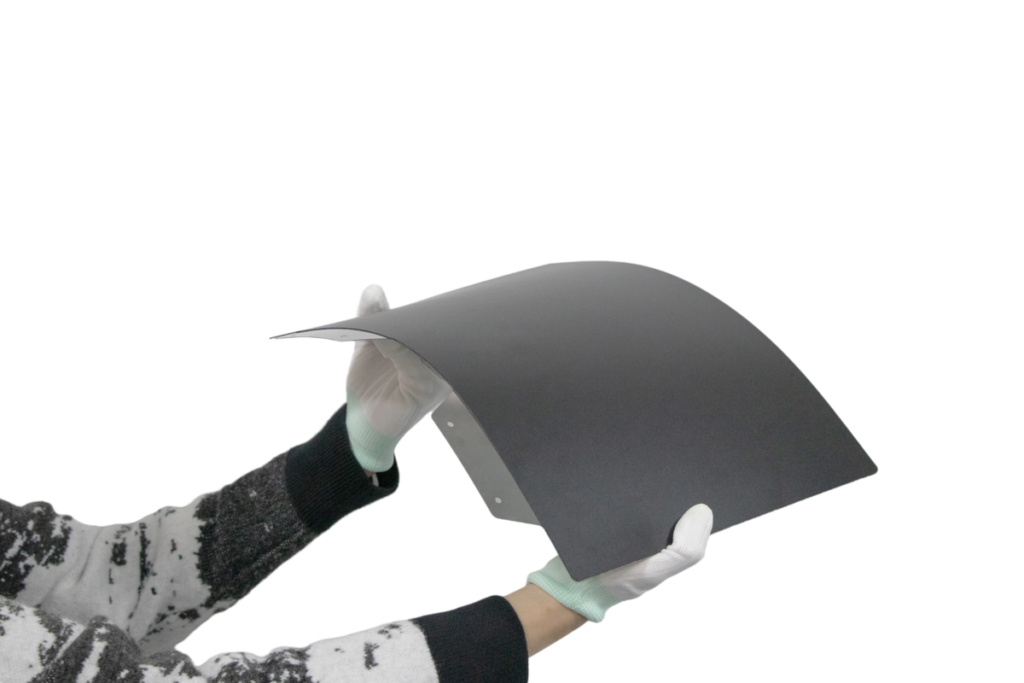

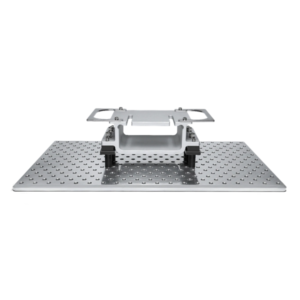

Flexible build plate for easy part removal

Printing volume

- Dual: 260x260x260mm

- Single: 305x260x260mm

Intelligent design of the FUNMAT PRO 310

- Automated mesh leveling

- 7-inch smart screen with INTAMTOUCH 2023

- The printing process can be monitored remotely through the camera, and can be controlled remotely via INTAMSUITE 2023

- Industry 4.0 ready with API/SDK for implementation into production facilities

INTAMTOUCH

- Intuitive User Interface

- Process Monitoring

- Team collaboration

Reviews

There are no reviews yet.