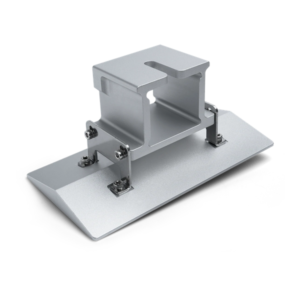

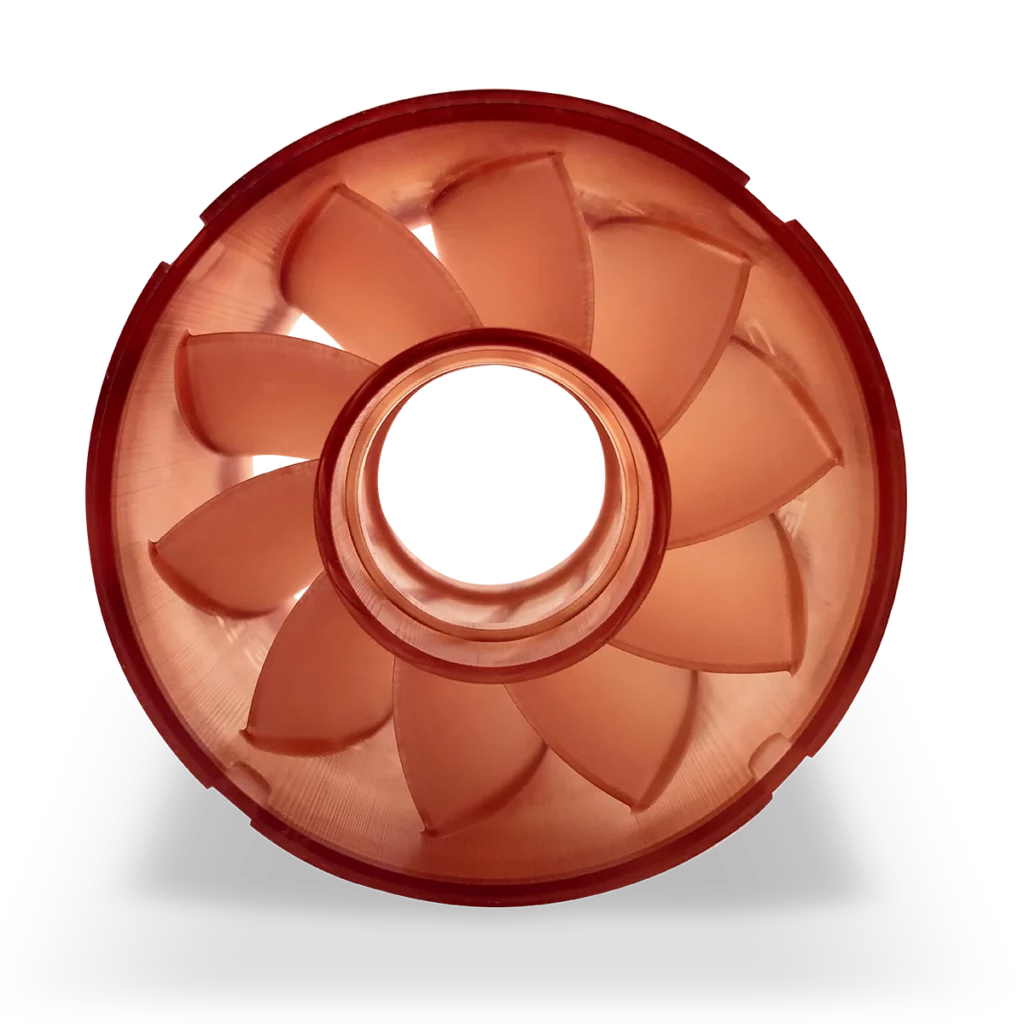

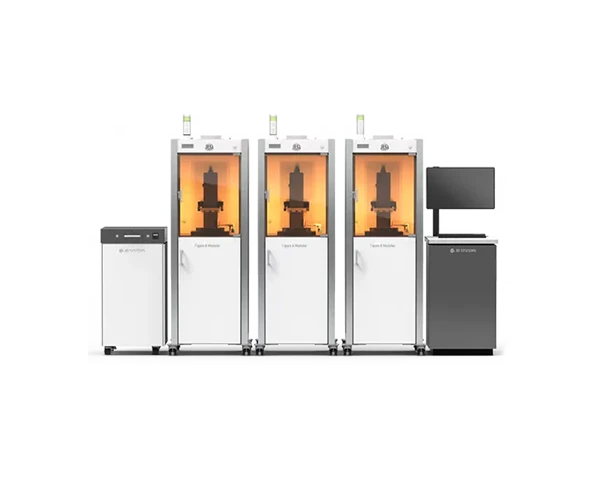

Figure 4 Modular

SCALABLE, SEMI-AUTOMATED 3D MANUFACTURING SOLUTION DESIGNED TO SCALE WITH GROWTH

- Super high speed with non contact technology

- Scalable up to 24 unit for future production

- Production grade material, Long term usage

- High precision & high repeatability (CPK>2)

- Intelligence software

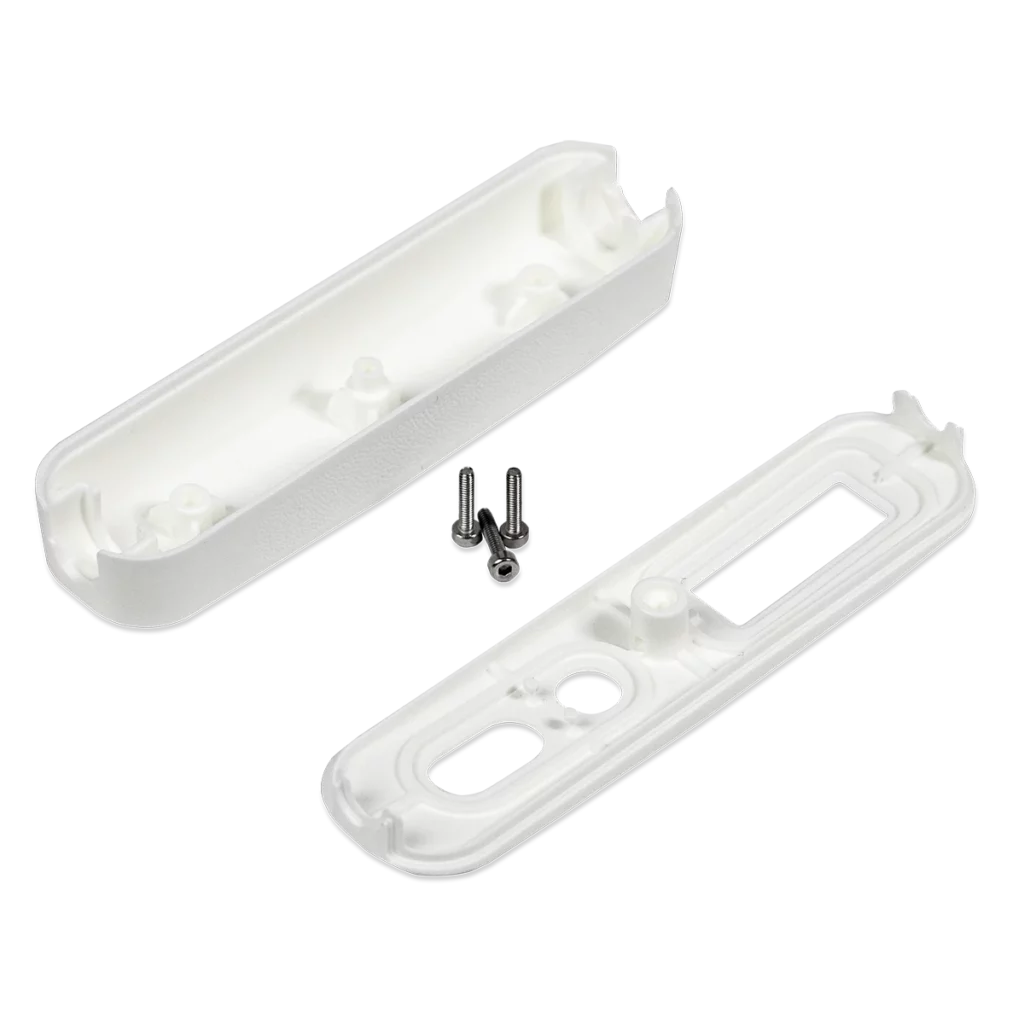

Figure 4 Modular Product Feature

Figure 4 Modular is a scalable, semi-automated 3D production solution that grows with your business, enabling capacity to meet your present and future needs, up to 10,000 parts per month, for unprecedented manufacturing agility. With expandable capacity up to 24 print engines, automated job management and queuing, automated material delivery, and centralized post-processing, Figure 4 Modular’s end-to-end digital manufacturing workflow is ideal for low to mid-volume production and bridge manufacturing. In addition, each printer can run different materials and different jobs as part of a single high throughput line serving a multitude of parts being produced.

Modular Scalability

Low Operations Cost

Unparalleled Flexibility

Figure 4 Modular’s individual printers enable simultaneous production of a wide variety of part sizes and shapes, in multiple materials for a diverse range of parts for production and prototyping.

ABOUT THIS PRINTER

- Replacement of traditional molding and cast urethane processes

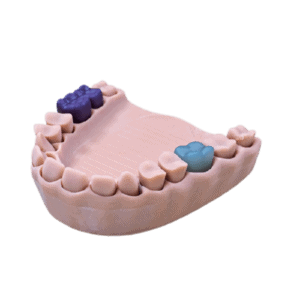

- Rapid functional prototyping and fast concept models

- End-use durable plastic parts

- Low volume bridge manufacturing

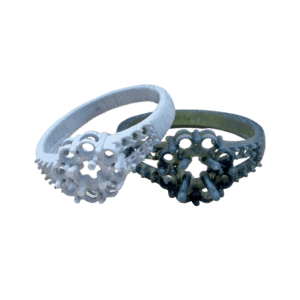

- Short run production of plastic articles

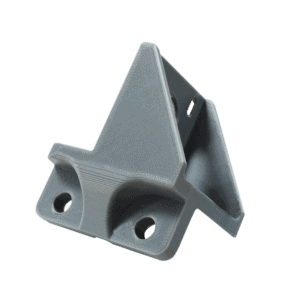

- Jigs and fixtures

- Rapid tooling -molds and master patterns

- Consumer high temperature applications with transparency

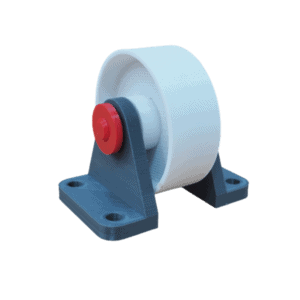

- Elastomeric parts –prototypes of grommets, seals, hoses, weatherstripping, tubes, gaskets, spacers and other vibration dampening components

- Medical applications

- Semi-automated solution reduces labor

- Ability to run different part geometries and materials in each print unit

- Scalability enables lower initial system acquisition price

- Rapidly expand capacity as demand increases

- Layout flexibility

- Six Sigma quality and repeatability

- High throughput and productivity

- Same day print and ship

- Low total cost of operations

- Accelerated time-to-market vs. traditional manufacturing

- Eliminate tooling time and cost

- Efficient design iteration

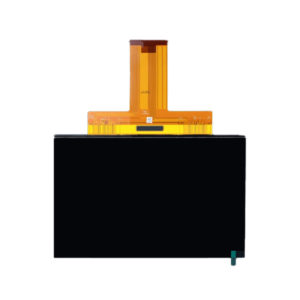

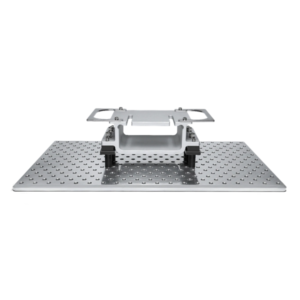

- Non-contact membrane Figure 4 technology

- Printable build volume (W x D x H): 124.8 x 70.2 x 346 mm (4.9 x 2.8 x 13.6 in)

- Industry-leading 3D Sprint software for file preparation and production

- Cloud connectivity for predictive and prompt service with 3D Connect

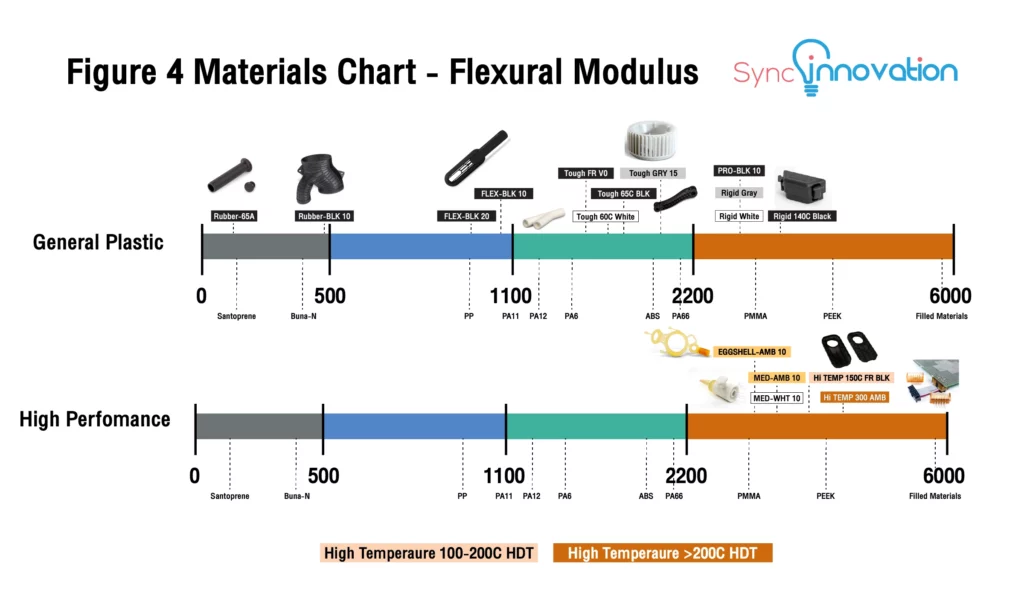

- Production-grade materials

- Scalable modular configurations

- Automated material handling

- Individual printer modules can be dedicated to individual materials

- Centralized post-processing (cleaning, drying, curing)