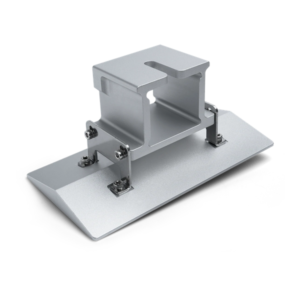

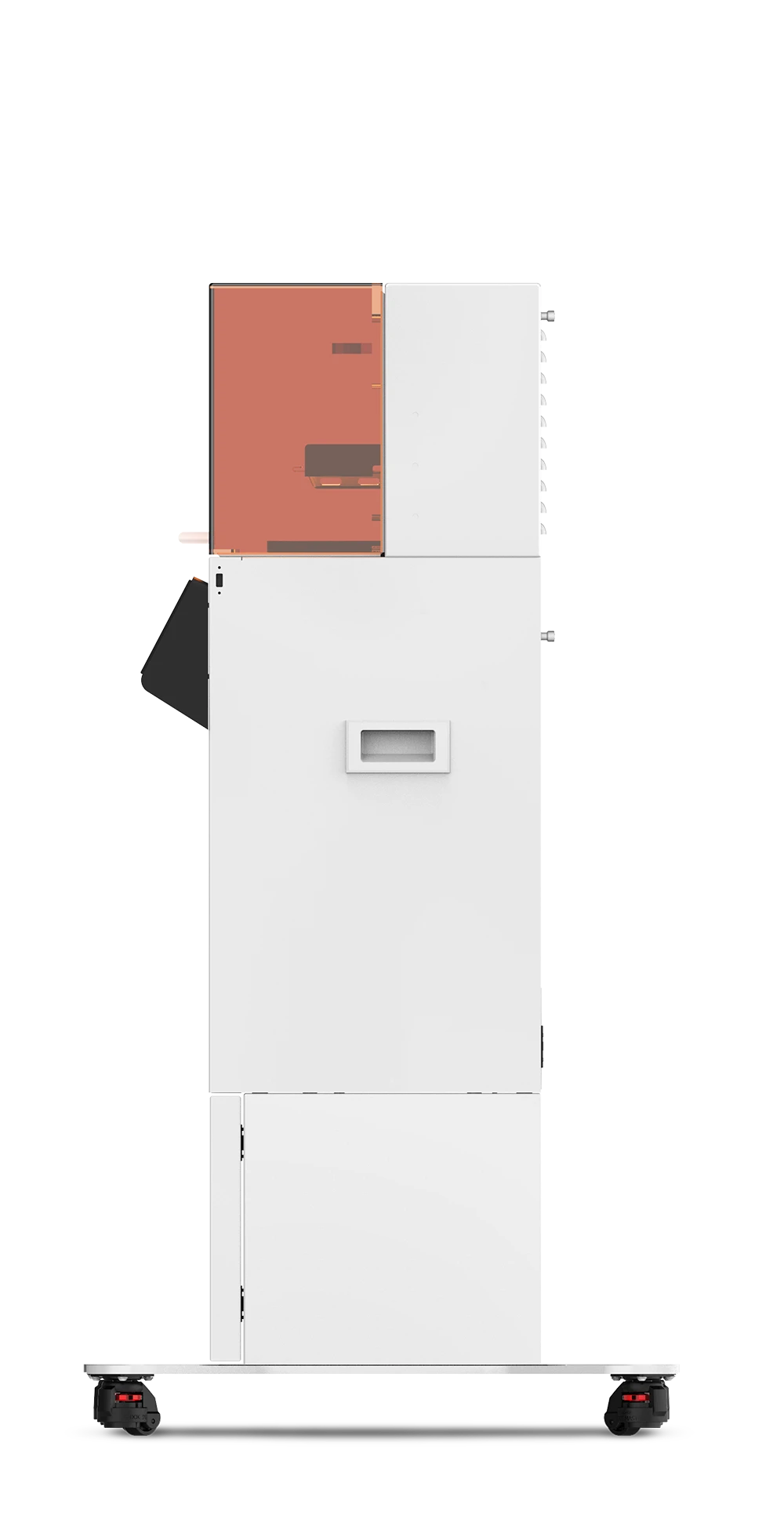

Figure 4 Standalone

Ultra-fast and affordable for same day prototyping and low-volume production

- Very high speed printing

- Wide range of production material

- High precision & high repeatability (CPK>2)

- Maximize your ROI

- Intelligence software

Figure 4 Standalone Product Feature

Affordability

Part of 3D Systems’ scalable, fully integrated Figure 4® technology platform, Figure 4 Standalone is an affordable and versatile solution for low volume production, and same-day prototyping for fast design iteration and verification, offering speed, quality, and accuracy with industrial-grade durability, service, and support. With a compact and easy-to-use design, Figure 4 Standalone delivers industrial-grade durability at an affordable price and low total cost of operations.

Versatility

Quick and easy material changeover allows for functional prototyping and production application diversity with the same printer. Featuring a manual material feed, it is augmented with separate post-processing units available for cleaning, drying, and curing.

Fast Turnaround

Achieve same-day functional prototyping and low volume production with ultra-high speeds. Figure 4 Standalone offers quality, accuracy, and Six Sigma repeatability (Cpk > 2) with industrial-grade durability, service, and support. Figure 4 Standalone was designed for ease-of-use and includes file preparation and print management with 3D Systems 3D Sprint software.

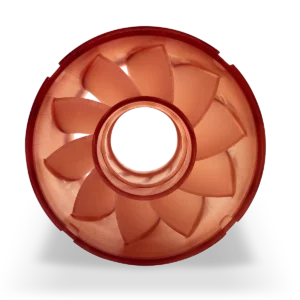

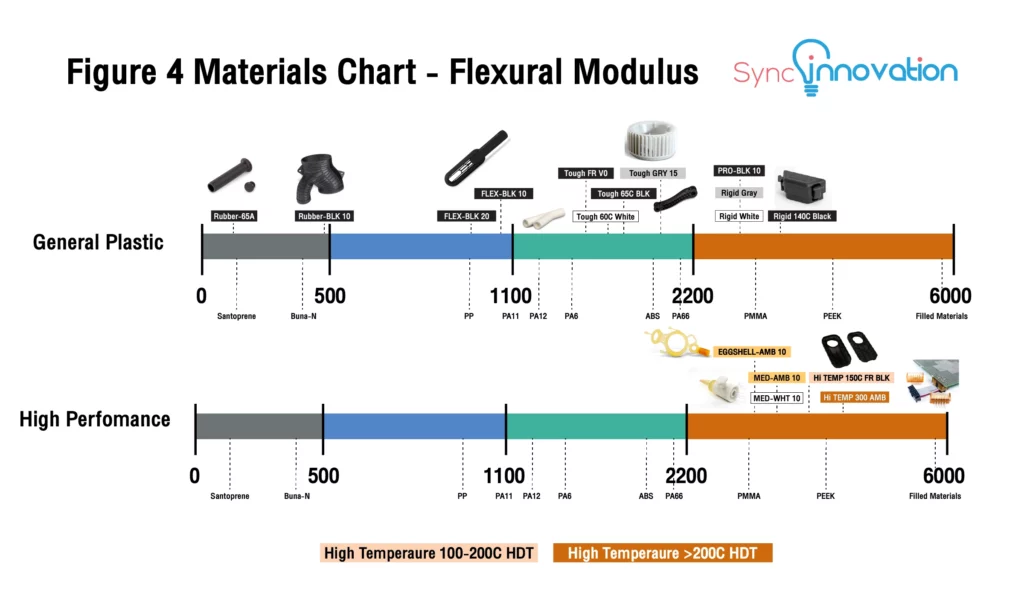

Broad Range of Materials

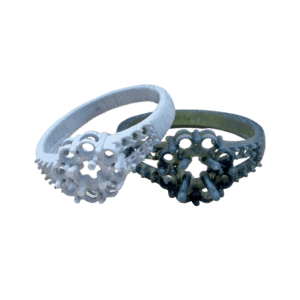

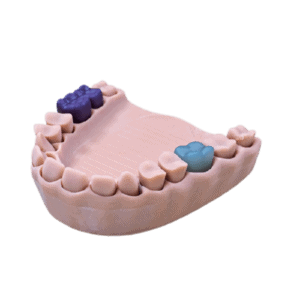

3D Systems’ Material Design Center has over 30 years of proven R&D experience and process development expertise. The broad and expanding range of materials available for Figure 4 Standalone addresses a wide variety of applications needs, for functional prototyping, direct production of end-use parts, molding and casting, and includes rigid and durable with thermoplastic-like behaviors, rubber-like, castable, heat resistant, and biocompatible capable materials.

ABOUT THIS PRINTER

- Replacement of traditional molding and cast urethane processes

- Rapid functional prototyping and fast concept models

- Investment casting patterns for jewelry

- End-use durable plastic parts

- Short run production of plastic articles

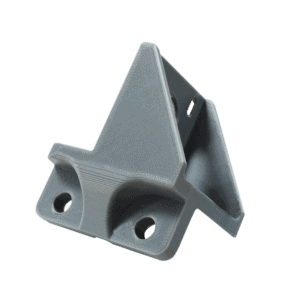

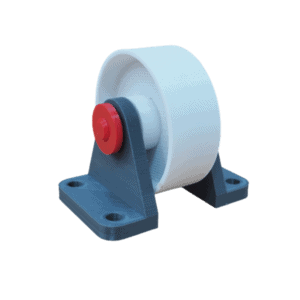

- Jigs and fixtures

- Rapid tooling -molds and master patterns

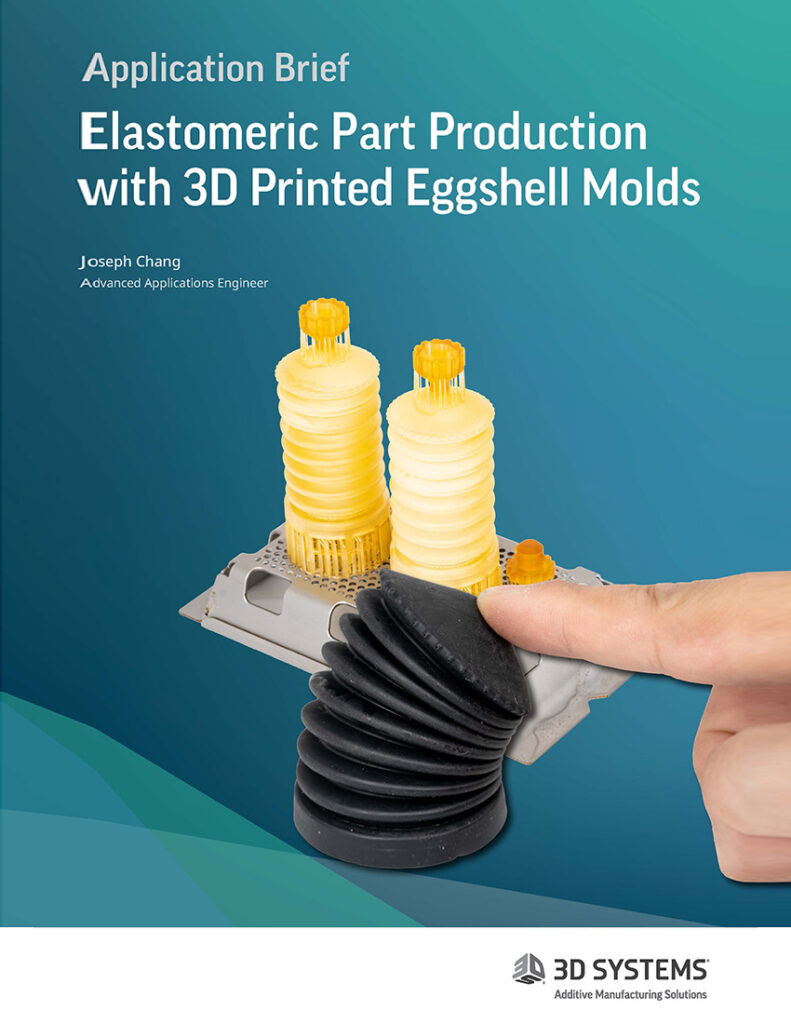

- Elastomeric parts –prototypes of grommets, seals, hoses, weatherstripping, tubes, gaskets, spacers and other vibration dampening components

- Medical applications requiring biocompatibility and/or thermal resistance

- Affordable initial investment

- High throughput vs. competitive 3D printing technologies

- Industrial-grade durability

- Print and use same day

- Low total cost of operations

- Application flexibility

- Efficient design iteration

- Six Sigma quality and repeatability

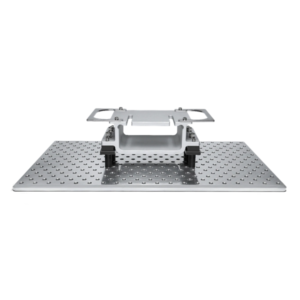

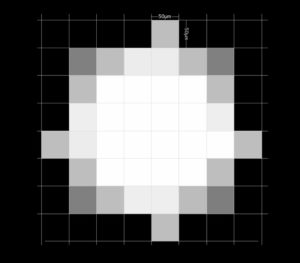

- Non-contact membrane Figure 4 technology

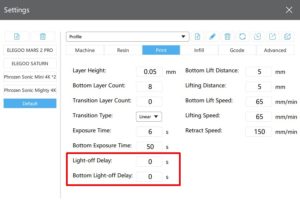

- Printable Build Volume (W x D x H):124.8 x 70.2 x 196 mm (4.9 x 2.8 x 7.7 in)

- Resolution 1920 x 1080 Pixel

- Industry-leading 3D Sprint software for file preparation and production

Cloud connectivity for predictive and prompt service with 3D Connect capability. - Production-grade materials

- Compact printer footprint

- Manual material feed

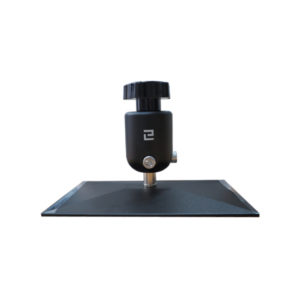

- Separate, manual post-curing unit, required