Why Bluecast X-One ?

- It provides perfect casting results with any type of investments and burnout cycles. It is compatible with low-temperature burnout (although we recommend a last stage temperature of 700°C or 1292°F, everything is completely burned out at 650°C or 1202°F)

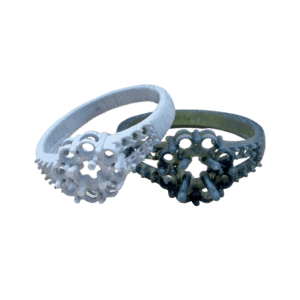

- you can cast any kind of pattern with text, engravings, micropavè, etc., in any casting house or service

- It is free from toxic and carcinogenic components

- There is no shrinkage at all

- It emits low fumes during burnout and has very low VOC (volatile organic compound) levels, with a negligible smell

- This resin is your best choice for solid parts

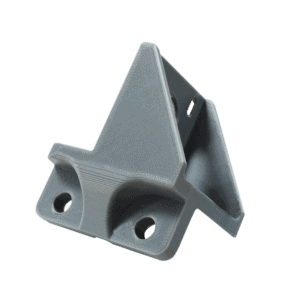

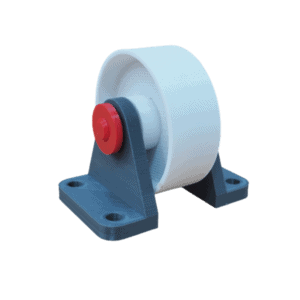

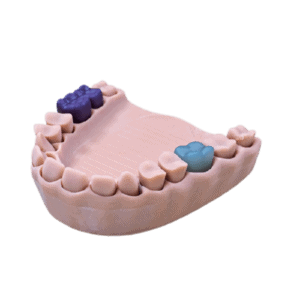

ตัวอย่างงาน Bluecast X-One V2

ขั้นตอนการ Post Processing หลังพิมพ์เสร็จ

มีความสำคัญมากส่งผลต่อความสามารถในการหล่อชิ้นงาน ควรศึกษาขั้นตอนและอุปกรณ์ที่ใช้ในการล้างให้เหมาะสม

FAQ About BlueCast

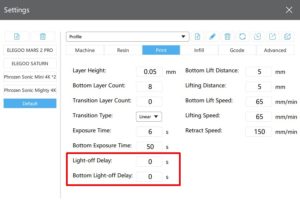

การตั้งค่า Resin Profile

Download All Resin Profile (คลิก)

Why are BlueCast resins more expensive compared to competitors?

BlueCast resins have a higher price due to our commitment to using only advanced polymers sourced from European, American, and Korean suppliers. Our resins are free from toxic and carcinogenic components, and we continually strive to minimize the presence of irritant chemicals. To ensure consistent performance over time and eliminate variations between production batches, we thoroughly test all raw materials before utilizing them.

Can I use BlueCast resins for jewelry production or are they only for prototypes?

Our mission is to develop castable resins that can rival wax in terms of accuracy and burnout. At BlueCast, we have a dedicated Jewelry Manufacturing Department that enables us to gain a deep understanding of the needs of goldsmiths and rigorously test the performance of our products. With our new X-One and X-Filigree V2 resins, which utilize proprietary polymers, we can print in the morning and cast in the evening. These resins are compatible with standard wax burnout (12 hrs.), fast burnout (6 hrs.), and ultra-fast burnout (2 hrs.).

Can I use BlueCast resins and wax models in the same flask?

All our “X-Resins” have been developed to perform similarly to wax. X-One and other specific resins are the first castable resins that melt like wax with any investment, burnout, and oven.

Do BlueCast resins require special investments?

No, they do not require phosphatic or special investments. We strongly suggest to follow the mixing time and instructions provided by the manufacturers. For solid and heavy designs such as chevaliers and celebration rings, we recommend allowing the flask to rest for 4 hours before casting.

Why are BlueCast resins the most used for jewelry production?

BlueCast resins are the preferred choice because they are incredibly easy to print, eliminating the need for lengthy post-processing or wasting time after printing. They are compatible with all burnout processes and do not require any special investments to achieve perfect casting results.

What is the recommended burnout process for your resins?

Although our castable resins are compatible with all burnouts, our preferred method is as follows:

CELCIUS (°C)

- 0-150°C: Ramp up temperature

- 150°C – 3 hrs: Hold at 150°C for 3 hours

- 150°C – 700°C: Ramp up temperature

- 700°C – 3 hrs: Hold at 700°C for 3 hours

- Down to casting temperature

- Ramp 8 degrees/min

Fahrenheit (°F)

- 0-300°F

- 300°F – 3 hrs

- 300°F – 1256°F

- 1250°F – 3 hrs

- Ramps 47 degrees Fahrenheit /min

Reviews

There are no reviews yet.